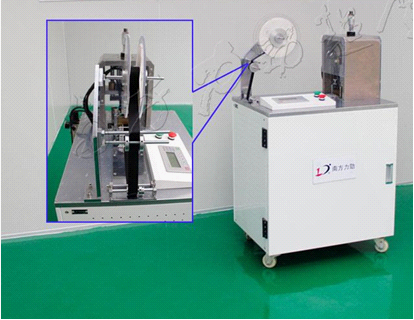

一、Device Description:

The belt cutting machine, composed of a cutter and a knife frame, the knife holder is installed on a base, and its innovation point is: a symmetrical vertical mounting plate is fixed on the base, and the movable mounting frame knife holder is vertically guided between the mounting plates, the top of the tool holder is horizontally fixed with a cutter, the tool holder is driven by a cam mechanism driven by a stepper motor at its bottom to achieve vertical rise and fall, a horizontal cutting belt platform is fixed under the cutting knife, and a feed roller driven by a servo motor is installed on the surface of the cutting belt platform, The stepper motor and servo motor are connected to the controller mounted on the base by a control line. The present invention has compact structure, the whole machine occupies less space, the design is scientific and reasonable, the tool holder is controlled by the controller by the stepping motor (feed roller through the servo motor), the whole machine has a high degree of automation, high processing efficiency, high precision, and easy operation.

二、Process requirements:

1. The length of the cutting belt is accurate to 1mm;

2. Precise positioning (fixed length of cutting belt)

三、System Composition:

The panel controls the length, speed, number of sheets and other parameters of the cutting strip so that the PLC sends pulses to the servo drive to let the servo motor realize the action.

四、System working principle and wiring instructions:

The servo drive receives a pulse signal from the PLC to control the motor to achieve the set action to obtain the required cutting belt length and speed.

The wiring diagram is as follows:

五、Parameter setting:

|

功能代码

|

代码名称

|

设定参数

|

使用说明

|

|

PA-1

|

型号代码

|

2A-30

|

同伺服电机相匹配

|

|

PA-4

|

控制方式选择

|

0

|

位置控制

|

|

PA-5

|

速度比例增益

|

150

|

设置值越大,则刚度越大,过大容易出现振荡

|

|

PA-6

|

速度积分时间常数

|

20

|

设置值越小,则刚度越大,过小容易出现超调

|

|

PA-9

|

位置比例增益

|

100

|

设置值越大,则刚度越大,过大容易出现振荡或超调

|

|

PA-12

|

位置指令脉冲分频分子

|

1

|

设置相应值可以很方便的与各种脉冲源相匹配

|

|

PA-13

|

位置指令脉冲分频分母

|

1

|

设置相应值可以很方便的与各种脉冲源相匹配

|

|

PA-14

|

位置指令脉冲输入方式

|

0

|

设置与上位机相应的脉冲输入方式,默认为脉冲+方向

|

|

PA-15

|

位置指令脉冲方向取反

|

0

|

改变此参数可以很简单的改变电机的旋转方向

|

|

PA-20

|

驱动禁止输入无效

|

1

|

屏蔽限位功能

|

|

PA-53

|

低4位输入端子强制ON控制字

|

0001

|

强制使能

|

Note: :Parameter 1 is the motor code, which needs to be set to the model of the selected motor.

According to the customer's setting, the simplest is to directly set the PLC parameters and start to see the ratio of the actual length and the required length.