一、Application introduction

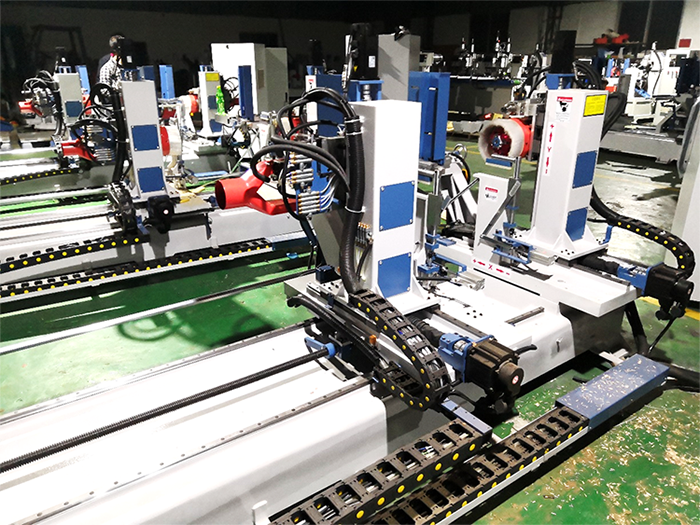

Tenoning machine is a more common and practical machine tool of automated woodworking machinery, which is used to process mortise for sofa boards, backrests, armrests, bed boards, coffee tables, TV cabinets and other splicing parts.

Wuhan Meixin EP1C servo drive equipped with Meixin motor has been used for seven years on a CNC double-ended tenon tapping machine.

二、Process requirements

1. Fast processing response and stable dimension.

2. The tenon head of high-speed processing cannot be deformed.

3. Work all day without abnormality in high dust environment.

三、System scenario

1. The control system adopts motion control card and industrial control computer all-in-one.

2. The servo power coverage section is 0.1KW to 7.5KW

四、Scenario advantages

High dimensional accuracy, can reach within one thread, customer requirements accuracy within ten wires, the price is close to the people.

五、Device description EP1C

1. Voltage: AC 220V

2. Power: 0.1kW-7.5kW

3. Control mode: position mode, speed mode, torque mode, position/speed, speed/torque, position/torque.

4. Working humidity 40%--80% (no condensation),

5. Storage -40 °C ~ 50 °C, working 0 °C ~ 40 °C.

6. Using advanced control algorithms and IPM intelligent modules, precise position control can be realized.

7. External brake resistor and DC reactor can be connected

8. Comes with communication interface to support remote upgrade.

9. Five programmable input terminals.

10. Three programmable output terminals.