一、Application introduction

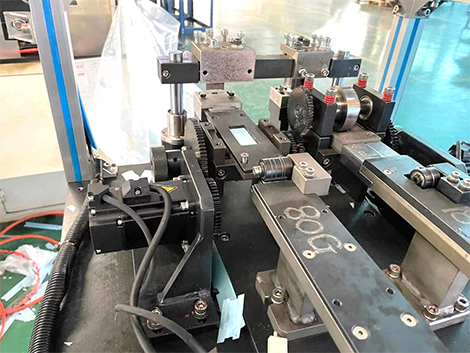

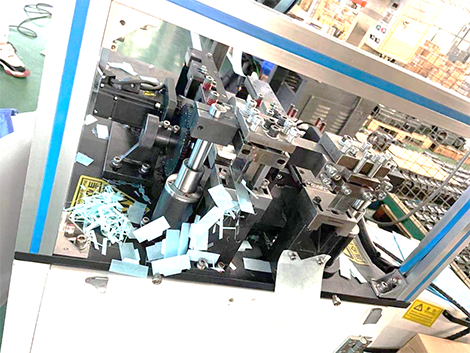

Automatic paper cutting machine, mainly used in the cutting process of fixed-length paper.

At present, the material cut is the insulating paper material between the stator skeleton of the servo motor, and the servo motor needs to be quickly positioned according to the length (unit mm) set on the HMI, and then the PLC triggers the cylinder action to cut off the material.

The whole part is divided into AB two stations, two sets of servos, can work separately according to different processes of insulation paper to set length, speed, acceleration and deceleration, etc.

二、Process requirements

1. The two independent stations can be started separately, and the required cutting size can be selected to meet the changes of different stator insulating paper processes

2. High-speed start and stop, accurate positioning error within plus or minus 10 wires

三、System scenario

1. The control system adopts Mitsubishi FX-3GA series PLC+EP5-TL04P servo drive (adapted to 60GSL01330 servo motor)

2. The electric control box requires a compact layout and a beautiful appearance of the equipment

四、Scenario advantages

1. EP5 series servo drive has compact structure and convenient installation, which can save the volume space of the control box

2. The control algorithm is improved, with a 23bit encoder, which effectively improves the control accuracy

3. Support remote firmware upgrade, convenient for later maintenance

五、Device description EP5

1. Voltage: AC 220V/AC380V

2. Power: 0.1kW~15kW

3. Communication interface: RS485, CANopen

4. Control mode: pulse (position mode) / analog (speed and torque mode)

5. Support 23-bit multi-turn absolute encoder, 17-bit magnetic coding