一、Application introduction

Common large and medium-sized air compressors are screw or piston compressors. When working, a motor drives the screw or piston to inflate the gas tank, when the pressure of the gas tank rises to the set maximum pressure, the clutch plate acts, the motor is automatically unloaded, the motor is idling, the screw or piston stops the compressed air, and the main motor of the air compressor runs in a star-shaped to triangular buck start-up and then runs at full pressure. The control mode of adding and unloading the air supply is the inlet valve switch control mode, that is, the valve is closed when the pressure reaches the upper limit, and the compressor runs without load; When the pressure reaches the lower limit, the valve is opened and the compressor is loaded and run. If the system pressure rises to the upper pressure value, the controller closes the intake valve and runs the compressor without load until the system pressure drops to the lower pressure limit, the controller makes the intake valve reopen, the exhaust valve closes, the compressor opens, the compressor runs at full load, and the above process is repeated. The exhaust volume and pressure of the air compressor are not unchanged in operation, and the air consumption often changes due to changes in working conditions, so the air compressor is always repeating the full load-unloading working mode when working. The working current at full load is close to the rated current of the motor, and the idling current when unloading is about 30-50% of the rated current of the motor, which is not useful work, but the idle loss of the machinery at the rated speed.

1、浪费大量的能源,导致生产成本的增加。

2、起动瞬间电流很大,对电网的稳定及其它用电设备的产生巨大的冲击,严重时甚至可能导致同一电网设备无法正常运行。

3、起动时对设备机械同样存在巨大的冲击,后续维护工作量大,维护成本高,制约生产效率。

4、经常卸载和加载的方法来调节,这样使整个气网压力经常变化,不能保持恒定的供气压力,另外也影响压缩机的使用寿命。

5、由于气压无法恒定,波动范围大,因此在一定程度上间接的影响了产品生产质量,在某些对气源气压要求苛刻的场合尤为明显。

6、自动化程度低,系统稳定性差,不利于维护, 需要专人操作停止或者启动机组来调节需求气量,但仍然无法有效的调节到合理范围,由于没有故障报警系统,不能快速有效的找到故障源以及排除故障。

二、System design

Meixin MR500 series inverter adopts leading open-loop vector control algorithm, strong overload output capacity, excellent performance, high reliability, built-in PID regulator, various parameters can be flexibly set, can well meet the control requirements.

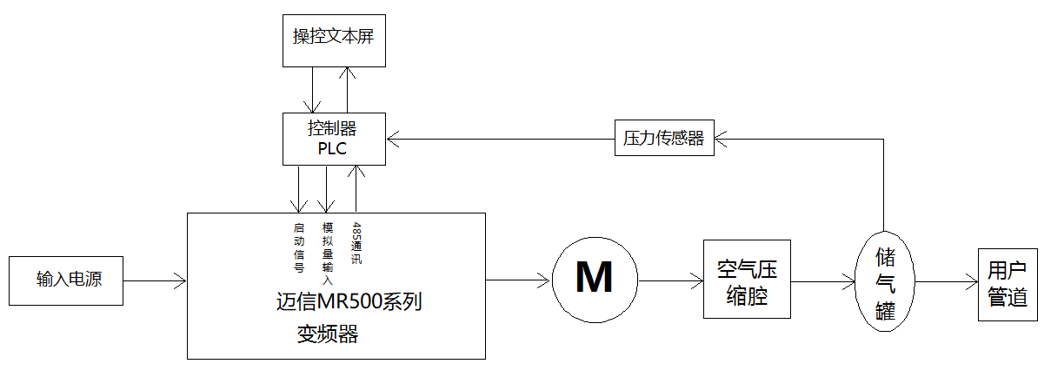

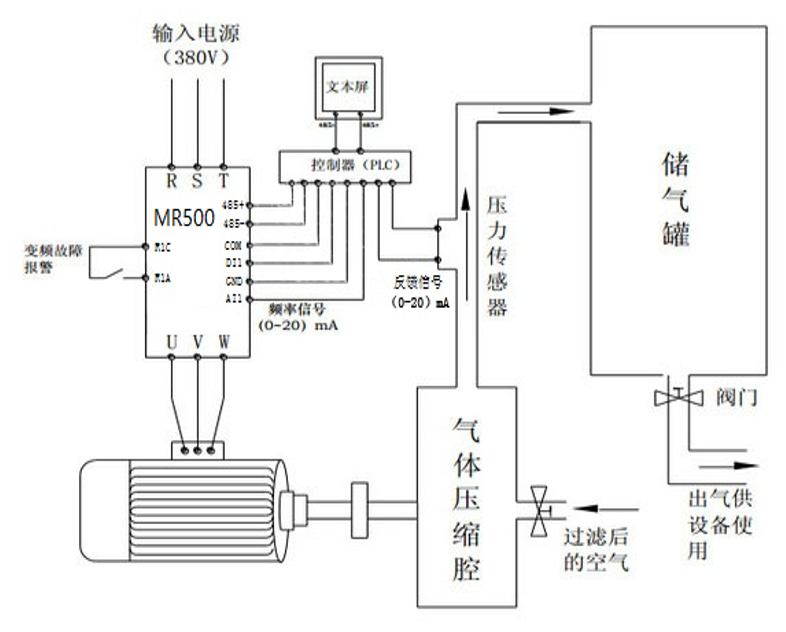

The air compressor adopts Meixin MR500 frequency converter and PLC controller to form the air compressor control system. The pressure value is set by the PLC controller, the pressure sensor detects the pressure of the gas supply pipeline network in real time, and converts it through the transmitter, outputs the standard 4-20mA signal, sends it to the PLC controller for feedback, and gives a 4-20mA signal to the analog input control frequency of the inverter after the PLC controller calculation. According to the requirements of the system air consumption, the output of the inverter is adjusted in real time, so as to adjust the speed of the compressor motor in real time to ensure the constant pressure of the pipe network. The inverter fault signal is sent to the system controller through the relay output; The system controller uses RS485 bus to read the status value of the inverter (output frequency, output voltage, output current, output power and fault code, etc.) through the MODBUS-RTU method.

The following figure is the flow chart of the air compressor system:

Principle of constant pressure air supply:

If the air supply flow > the gas flow rate, the frequency of the inverter is reduced and the motor speed is reduced;

If the air supply flow < the gas consumption flow, the frequency of the inverter rises and the motor accelerates;

If the air supply flow = the air consumption flow, the frequency of the frequency converter does not change, and the motor speed does not change.

Wiring diagram:

2.1 Advantages after the implementation of the project

1. Save electric energy:

After the constant pressure air supply system is put into operation, the air pressure of the gas tank can be kept within 2.5% of the set value, and the automatic emptying loss and the motor frequency can be reduced to 25HZ when there is no load.

2. Reduce noise and reduce environmental pollution:

Due to the realization of frequency conversion control, the constant pressure gas supply system basically eliminates the situation of emptying and gassing, thereby improving the pollution of noise to the environment.

3. Extend the service life of mechanical parts:

After using the power-saving system of the air compressor, the air compressor runs under the power frequency most of the time, which can significantly reduce the wear of mechanical components, extend the life of the machine, reduce maintenance costs and shorten the maintenance time.

4. Soft start is realized:

Reduce the impact of the starting current of the unit on the power grid, and at the same time can be flexibly repeated for multiple starts, avoiding the shortcomings of self-coupling buck starting in this regard.

5. Achieve constant pressure air supply:

After the system is put into operation, the reliability of air supply and the ability to adjust load changes are improved, the constant air supply pressure is guaranteed, and the stability of product quality is further guaranteed.

6. Reliable operation, failure rate is almost zero:

The system is equipped with overload, loss of voltage, undervoltage, overcurrent, phase loss and other protection functions, and the operation is reliable.

三、Apply effects