一、Equipment Introduction:

The feeder is a machine for conveying materials, whether it is a light industry or heavy industry are indispensable equipment, the feeder is a machine that uses the automatic feeder machine movement force to force the material and transport the material.

二、Equipment features:

In today's society, more and more manufacturers use mechanized transportation, this way to replace human labor will become inevitable, it has a high degree of accuracy, and time-saving, labor-saving also greatly reduces labor intensity, reduces labor costs and saves human resources. It really achieves low cost and high return. In today's era of rapid development, this automation product will be favored and liked by more and more manufacturers!

三、System Composition:

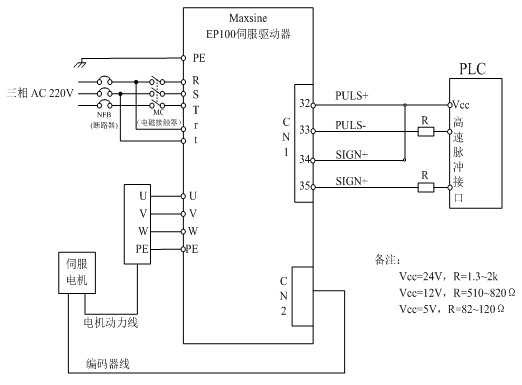

Basically, one to two sets of servo motors are composed of drives and PLCs.

四、System working principle and circuit diagram:

The upper computer sends a position command pulse to the driver, so that the workbench moves to a more accurate position, and cooperates with other equipment to complete the processing of the product.

五、驱动相关参数设置:(以EP100为例)

|

功能代码

|

代码名称

|

设定参数

|

使用说明

|

|

PA002

|

型号代码

|

A103

|

同伺服电机相匹配

|

|

PA004

|

控制方式选择

|

0

|

位置控制

|

|

PA005

|

速度比例增益

|

150

|

设置值越大,则刚度越大,过大容易出现振荡

|

|

PA006

|

速度积分时间常数

|

20

|

设置值越小,则刚度越大,过小容易出现超调

|

|

PA009

|

位置比例增益

|

100

|

设置值越大,则刚度越大,过大容易出现振荡或超调

|

|

PA029

|

位置指令脉冲分频分子

|

1

|

设置相应值可以很方便的与各种脉冲源相匹配

|

|

PA030

|

位置指令脉冲分频分母

|

1

|

设置相应值可以很方便的与各种脉冲源相匹配

|

|

PA035

|

位置指令脉冲输入方式

|

0

|

设置与上位机相应的脉冲输入方式,默认为脉冲+方向

|

|

PA036

|

位置指令脉冲方向取反

|

0

|

改变此参数可以很简单的改变电机的旋转方向

|

|

PA098

|

低4位输入端子强制ON控制字

|

1

|

强制使能

|