一、Device description

CNC punching machine is an automatic machine tool equipped with a program control system. The control system is able to logically process and decode programs with control codes or other symbolic instructions to make the press act and machine the part.

二、Features of CNC punching machines

The operation and monitoring of the CNC punching machine are all done in this CNC unit, which is the brain of the CNC punching machine. Compared with ordinary punching machines, CNC punching machines have the following characteristics:

● High processing accuracy, with stable processing quality;

● Large processing area: 1.5m*5m processing format can be completed at one time;

● Multi-coordinate linkage, complex shape parts can be processed and cut and shaped;

● When the machining parts are changed, generally only the CNC program needs to be changed, which can save the production preparation time;

● The punching machine itself has high precision, large rigidity, and can choose a favorable processing amount, with high productivity;

● The degree of automation of the punching machine is high, which can reduce the labor intensity;

● Simple operation, with certain basic computer knowledge training can be used in 2-3 days;

三、System composition

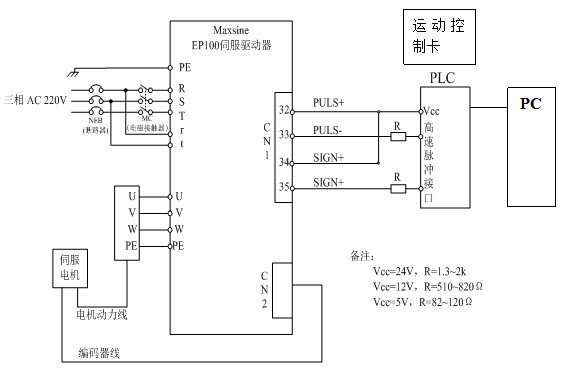

The system consists of two sets of servo drives and servo motors, plus a machine, a computer controller and a traditional punching machine. As shown in the following figure:

四、How the system works

The computer is programmed by software and displayed on a monitor in graphical form. With a few simple operations, a position command pulse is sent to the driver to achieve precise positioning. Cooperate with the stamping speed of the punching machine to complete the processing of various products.

The relevant route diagram is as follows:

五、Drive-related parameter settings:

|

功能代码

|

代码名称

|

设定参数

|

使用说明

|

|

PA002

|

型号代码

|

|

同伺服电机相匹配

|

|

PA004

|

控制方式选择

|

0

|

位置控制

|

|

PA005

|

速度比例增益

|

150

|

设置值越大,则刚度越大,过大容易出现振荡

|

|

PA006

|

速度积分时间常数

|

20

|

设置值越小,则刚度越大,过小容易出现超调

|

|

PA009

|

位置比例增益

|

100

|

设置值越大,则刚度越大,过大容易出现振荡或超调

|

|

PA029

|

位置指令脉冲分频分子

|

1

|

设置相应值可以很方便的与各种脉冲源相匹配

|

|

PA030

|

位置指令脉冲分频分母

|

1

|

设置相应值可以很方便的与各种脉冲源相匹配

|

|

PA035

|

位置指令脉冲输入方式

|

0

|

设置与上位机相应的脉冲输入方式,默认为脉冲+方向

|

|

PA036

|

位置指令脉冲方向取反

|

0

|

改变此参数可以很简单的改变电机的旋转方向

|

|

PA098

|

低4位输入端子强制ON控制字

|

1

|

强制使能

|