一、Application introductionLaminating machineFunction: The surface of the coil is laminated or compounded by a variety of substrates through the plastic extruder to achieve the effect of improving the tensile strength and moisture-proof performance of the product.

Uses: widely used in chemical bags in chemical metallurgy industry; fertilizer bags and cement bags; rice bags and sugar bags in the food industry; Aquatic products, pet feed bags, etc.

Applicable substrates: PP and LDPE woven fabrics, non-woven fabrics, paper, etc.

Performance characteristics: double extruder, double laminating machine to complete the double-sided lamination of the substrate at one time. Equipped with the latest double-sided color film automatic plate matching system, this system can make the front and back double-sided pattern alignment more accurate and faster, the system is easy to operate, effectively save labor.

二、Process requirements

1. The response requirements are high, and the start and stop requirements are more stable

2. The pulse frequency of the driver should be high

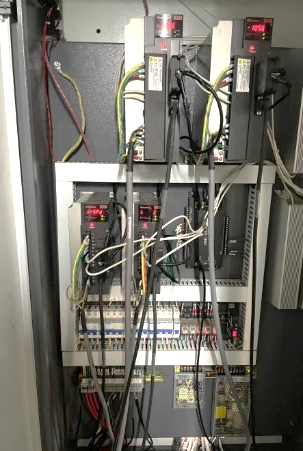

3. 7×24 hours high-speed and stable operation三、System scenario1. Two EP1C-TH20 drives control the forward and reverse directions of the motor, and run for a long time without abnormality under the conditions of high and low frequency and speed through the pulley

2. Two EP1C-TH50 drives control large motors that can withstand more loads and have higher power

四、Scenario advantages1. High servo stability

2. 7×24 hours working environment without failure

3. Faster response and smoother start and stop

4. It can be converted frequently between high and low frequencies五、Device description EP1C 1. Voltage: AC 220V/380V

2. Power: 0.1kW~15kW

3. Optional built-in/external brake resistance interface

4. Communication mode: USB

5. Control mode: vector control

6. Standard 5V differential signal input; There are 5 programmable input terminals and 3 programmable output terminals; Speed and torque modes can be controlled both internally and analogly

7. Support Modbus protocol, origin regression function, gain switching and mechanical resonance notch

8. Siemens CNC system exclusive specifications