Application of EP3E-PN in filling line manipulator

2022-03-01

一、Application introduction

Wuhan Meixin Electric Co., Ltd. cooperates with an equipment co., LTD.'s bottled oil/bottled water packaging production line in Guangzhou, which mainly completes transportation, sorting, labeling and packing. There are four stations on the conveyor tray, and the conveyed material barrels are loaded into four card positions on the turntable, and then picked up by the robotic arm and put into the next step of filling, and then grabbed by the robotic arm into the next station to cap, label, transport and pack.

二、Process requirements

1. The single handling weight of the production process is 24kg

2. Continuous work, stability, efficiency and precision

3. PROFINET bus control is adopted

三、System scenario

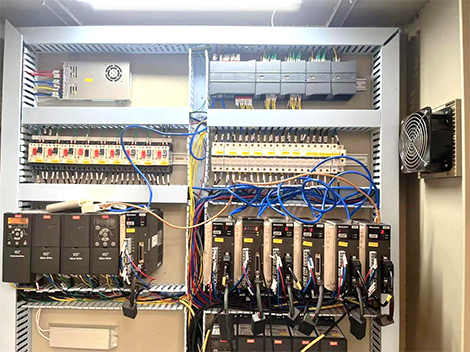

1. The control system adopts Siemens 1200PLC, equipped with seven servo drives and absolute motors

2. The servo power section covers 100W~7.5kW

四、Scenario advantages

1. The servo acceleration is fast and the operation is stable

2. 7×24 hours working environment without failure

3. Full bus scheme, convenient wiring, convenient maintenance, can provide rich diagnostic letters

五、Device description EP3E-PN 1. Voltage: AC 220V/380V

2. Power: 0.1kW~7.5kW

3. Communication interface: PROFINET

4. Control mode: support process object standard messages 3, 5, and Siemens messages 102, 105, integrated positioning function, support Siemens message 111, compatible with SINA_POS (FB284 function block), support auxiliary messages 750, 860, etc., in subsequent updates

5. Support 23-bit multi-turn absolute encoder