一、 introduction

The control of the water supply system is ultimately to meet the user's demand for flow. High demand during peak periods, fast water supply is required; A certain tube pressure should be maintained at low peaks. The most fundamental control object is the flow rate, and the pressure is used as a parameter variable to control the flow rate. If the pressure in a certain part of the water supply system is kept constant, it is ensured that the water supply capacity and water flow at that place are in a balanced state to meet the water needs of users.

Usually in the same water supply system, multiple commonly used pumps are set up, multiple pumps are fully opened when the water supply is large, and one or two pumps are turned on when the water supply is small. When using frequency conversion speed regulation for constant pressure water supply, two ways are used: one is that all pumps are equipped with a frequency converter; The second is that each pump is equipped with a frequency converter.The latter method automatically adjusts the output frequency of the inverter through PID operation according to the pressure feedback signal, changes the motor speed, and finally achieves the purpose of constant pressure of the pipe network, which is a closed-loop loop, which is simpler, but the cost is high. The former method has low cost and no worse performance than the latter, but the control program is more complex, which is the future development direction.

二、 Control principle and scheme

The use of frequency conversion speed regulation to achieve constant pressure water supply, compared with the use of regulating valves to achieve constant pressure water supply, the energy-saving effect is very significant (can be calculated according to the specific situation). The advantages are:

1. Starting balance, the starting current can be limited within the rated current, so as to avoid the impact on the power grid when starting;

2. Due to the reduction of the average speed of the pump, the service life of the pump and valve can be extended;

3. It can eliminate the water hammer effect during starting and stopping.

Generally speaking, when a motor is controlled by a frequency converter, it is only necessary to make the motor capacity of the frequency converter match the actual motor capacity. When a frequency converter controls two motors at the same time, in principle, the motor capacity of the frequency converter should be equal to the sum of the capacities of the two motors. However, if the water consumption at peak load is much different from the water supply of the two pumps at full speed, the capacity of the inverter can be considered appropriately, but attention should be paid to leaving sufficient capacity.

Although the water pump is running at low speed, the operating current of the motor is small. However, when the user's water consumption changes frequently, the motor will be in a frequent state of rising and decreasing, and the current of rising and decreasing, can slightly exceed the rated current of the motor, causing the motor to overheat. Therefore, the thermal protection of the motor is required.For this kind of temperature rise accumulated due to frequent rise and decrease, the electronic thermal protection function in the inverter is difficult to play a protective role, so thermal relays should be used for thermal protection of the motor.

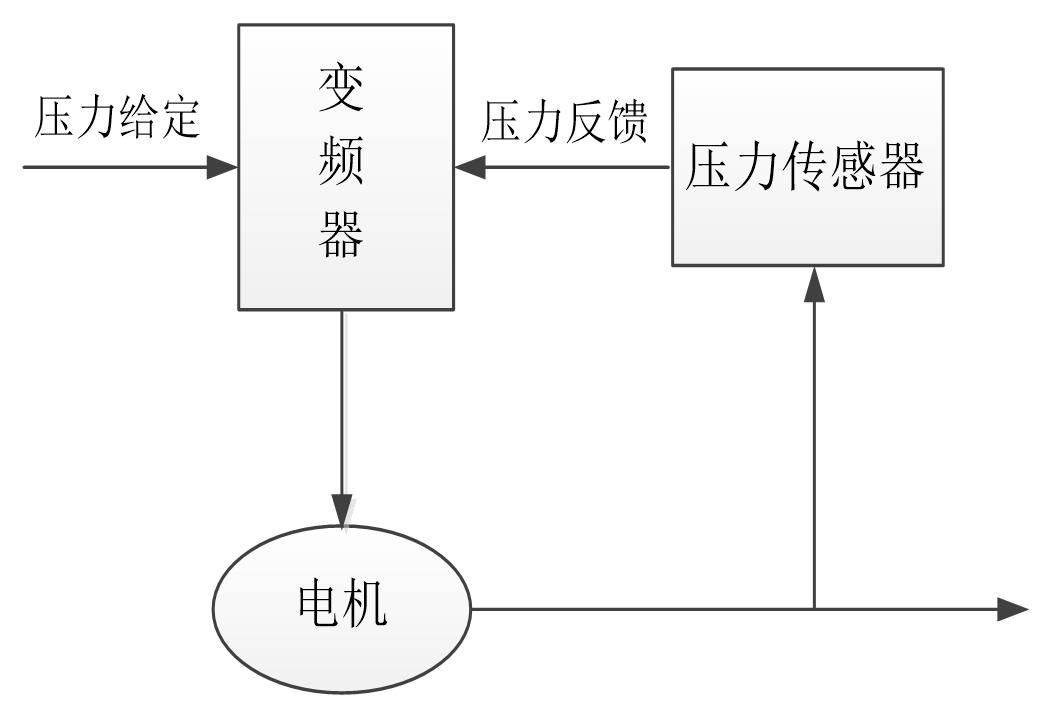

In terms of main function presetting, the highest frequency should be the rated frequency of the motor as the highest working frequency of the inverter. The speed up and down time is adjusted by the built-in PID of the frequency converter.The rising and falling times should be set as short as possible so as not to affect the dynamic response process determined by the PID regulator.The control principle is as follows:

三、 Inverter control features

1. Power saving

Optimized energy-saving control software enables maximum energy-efficient operation of the pump.

2、Water conservation

Set the pressure of the pipe network according to the actual water use, automatically control the water output of the pump, and reduce the phenomenon of water running and leakage.

3、Reliable operation

The soft start of the pump is realized by the frequency converter, so that the pump realizes the shock-free switching from power frequency to frequency conversion, prevents the impact of the pipe network, avoids the pressure of the pipe network exceeding the limit, and the pipeline breaks.

4、Networking capabilities

The full-Chinese industrial control configuration software is used to monitor each station in real time, such as the voltage, current, working frequency, pipe network pressure and flow of the motor. And it can accumulate the electricity consumption of each station, accumulate the water output of each pump, and provide various forms of printed reports for analysis and statistics.

5、Flexible control

Segmented water supply, regular water supply, manual selection of working mode (peripheral control circuit not yet available).

6、The self-protection function is perfect

If a pump fails, take the initiative to send an alarm message to the host computer, and start the backup pump at the same time to maintain the balance of water supply. In the unlikely event of a malfunction of the automated control system, the user can directly operate the manual system to maintain the water supply.

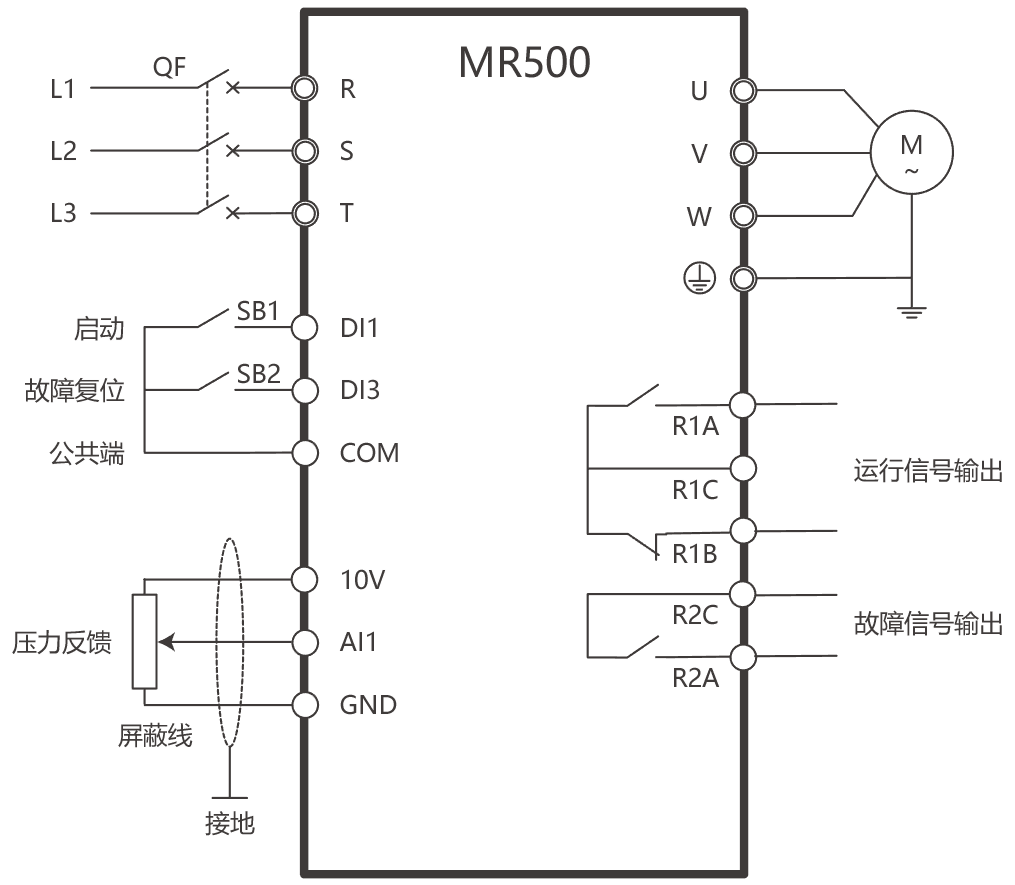

四、 Refer to the wiring diagram

五、 Refer to Setting Parameters