一、Application introduction

Wuhan Meixin Electric Co., Ltd. cooperated with a mechanical equipment Co., Ltd. to complete the application of woodworking turning and milling integrated machine, the production line can complete the initial processing of wood (external shape, milling of various shapes of grooves, punching), to achieve wood processing at one time. There are two sets of spindles at the station, which can realize the action of milling, turning and drilling respectively.

二、Process requirements

1. The path of the double spindle in the production process should be highly consistent

2. Continuous work, stability, efficiency and precision

3. Simple application and easy setup

4. The dust on site is large and must be able to resist dirt

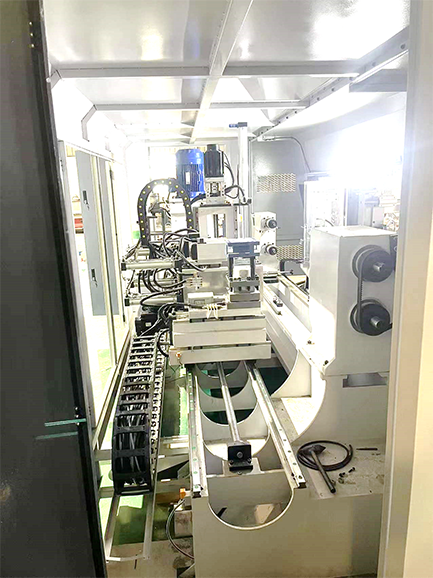

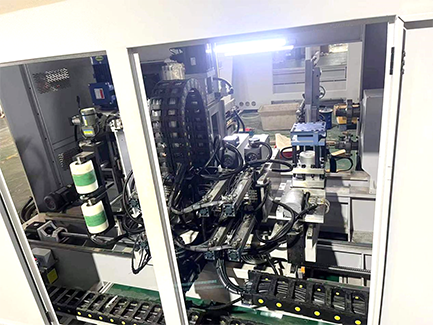

三、System scenario

1. The control system adopts the new generation CA65, equipped with 3 servo drives and standard incremental motors

2. The servo power section covers 100W~7.5kW

四、Scenario advantages

1. The servo acceleration is fast and the operation is stable

2. 7×24 hours working environment without failure

3. The protection level is qualified

五、Device description EP1C

1. Voltage: AC 220V

2. Power: 0.1kW~15kW

3. Using advanced control algorithms and IPM intelligent modules, digital control with accurate position can be realized

4. External brake resistor and DC reactor terminal can be connected

5. USB communication interface