一、Application introduction

With the rapid development of automobile, national defense, aviation, aerospace and other industries and the application of new materials such as aluminum alloys, the CNC machine tool processing industry has higher and higher requirements for high speed. CNC machine tool better solves the problem of complex, precise, small batch and multi-variety parts processing, is a flexible, high-efficiency automatic machine tool, represents the development direction of modern machine tool control technology, is a typical mechatronics product.

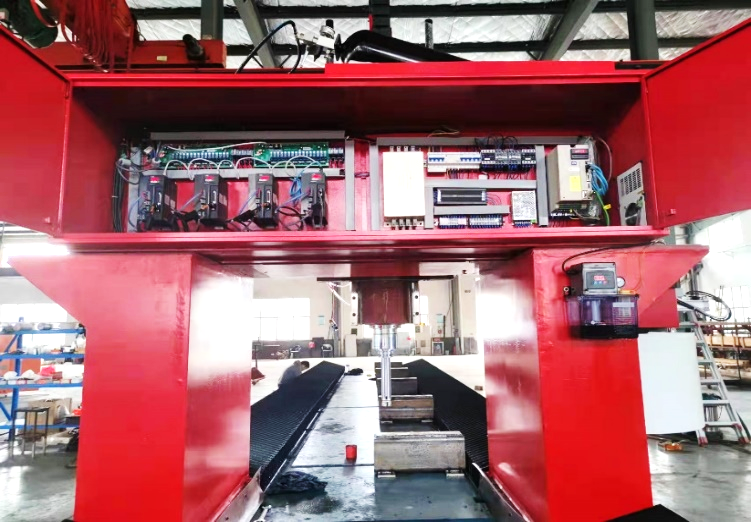

Wuhan Meixin EP3E-EC servo in a company's gantry milling machine equipment support:

二、Process requirements

1. Fully automatic control, fast response, high stability

2. High synchronization

3. Use EtherCAT bus control

4. 7× 24 hours of stable operation

三、System scenario

1. Baoyuan numerical control system + 4 EP3E-EC servos

2. The servo power section covers 100W~15kW

四、Scenario advantages

1. High production efficiency

2. 125μs minimum communication cycle, synchronous jitter time is less than 1μs

3. Control cycle: current loop 62.5μs, speed loop 62.5μs, position loop 62.5μs

4. Full bus scheme, easy maintenance, can provide rich diagnostic information

五、Device description EP3E-EC

1. Voltage: AC 220V/380V

2. Power: 0.1kW~15kW

3. Communication interface: EtherCAT

4. Control mode: CSP, CSV, CST, hm mode

5. Support encoder: 23bit incremental subdivision, 23bit multi-turn absolute value, etc

6. Support motor type: MA/MS rotary motor, MD/MR direct drive motor, support third-party motor