一、Application introduction

With the increase in the types of steel pipe quenching machine automation equipment and the more precise process, the steel pipe quenching machine automation equipment has been widely recognized by the market, and the market demand is strong.

二、Process requirements

1. Use PROFINET bus control

2. Meet the process requirements of quenching industry

3. Real-time monitoring of data information, stable operation in high temperature and harsh environment

三、System scenario

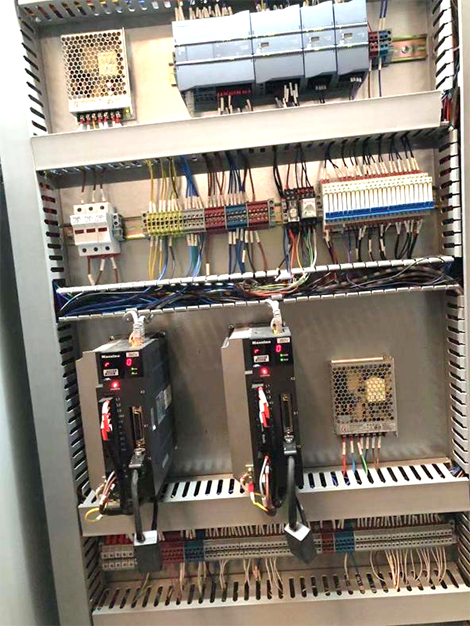

1. The control system adopts Siemens S7-1214PLC+2 sets of Meixin bus servo EP3E-PN

2. Configure speed mode message 3 control

四、 program advantages

1. PROFINET bus control, real-time monitoring of data information

2. Strong anti-interference ability, stable operation in harsh environment

3. The quenching process has high precision and high finish

五、Device description EP3E-PN

1. Voltage: AC 220V/380V

2. Power: 0.1kW~7.5kW

3. Communication interface: PROFINET

4. Support messages: support Siemens speed control mode messages 1, 3, 5, 102, 105, support Siemens position control mode message 111, support Siemens auxiliary messages 750, 860

5. Support function block: support process object and FB284 function block, FB285 function block, FB287 function block

6. Support 23-bit multi-turn absolute encoder