一、Device Description:

A polishing machine has several stations (polishing machine manufacturers can increase or decrease the process position according to customer requirements), polishing machine station with servo motor to drive rotation, station evenly distributed fixed on a central turntable, turntable with asynchronous motor with reducer to drive rotation, surrounded by a number of mechanical polishing wheels (similar to robotic arms), with asynchronous motor to drive the polishing wheel up and down, front and back, left and right displacement, with the polishing wheel rotation friction polishing body surface to achieve the purpose of polishing. When the surface of part of the polishing body is irregular, the polishing machine station needs to rotate back and forth for half a cycle.

二、Process requirements:

1. There is a large polishing rate to remove the damage layer of the grinding workpiece.

2. Accurate positioning (for irregular surfaces that cannot be rotated around the whole cycle).

3. Stable speed and torque (stepper motor is easy to stall).

三、System Composition:

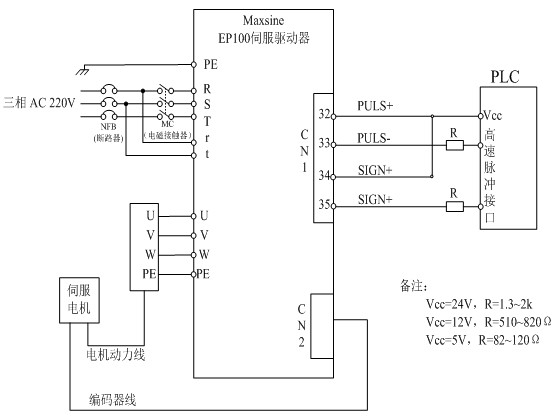

As shown in the figure, the polishing machine uses several sets of servo drives and servo motors, and the servo motors drive the station to rotate through the gears. The controller adopts PLC, and the PLC sends pulses to control the motor operation.

Figure 1: Polishing machine front

Figure 2: Polishing machine station

Figure 3: Servo drive

四、System working principle and wiring instructions:

The servo drive works in position mode, and by accepting the pulse signal of the PLC, the running direction and running speed of the motor can be adjusted through the PLC.

System schematic wiring diagram: (EP100 as an example)

Remarks: The company can provide finished encoder line and power line (cost charged)

五、Parameter setting:

|

功能代码

|

代码名称

|

设定参数

|

使用说明

|

|

PA-1

|

型号代码

|

2A-30

|

同伺服电机相匹配

|

|

PA-4

|

控制方式选择

|

0

|

位置控制

|

|

PA-5

|

速度比例增益

|

150

|

设置值越大,则刚度越大,过大容易出现振荡

|

|

PA-6

|

速度积分时间常数

|

20

|

设置值越小,则刚度越大,过小容易出现超调

|

|

PA-9

|

位置比例增益

|

100

|

设置值越大,则刚度越大,过大容易出现振荡或超调

|

|

PA-12

|

位置指令脉冲分频分子

|

1

|

设置相应值可以很方便的与各种脉冲源相匹配

|

|

PA-13

|

位置指令脉冲分频分母

|

1

|

设置相应值可以很方便的与各种脉冲源相匹配

|

|

PA-14

|

位置指令脉冲输入方式

|

0

|

设置与上位机相应的脉冲输入方式,默认为脉冲+方向

|

|

PA-15

|

位置指令脉冲方向取反

|

0

|

改变此参数可以很简单的改变电机的旋转方向

|

|

PA-20

|

驱动禁止输入无效

|

1

|

屏蔽限位功能

|

|

PA-53

|

低4位输入端子强制ON控制字

|

0001

|

强制使能

|

六、summary

This case is a product developed by our company and a famous domestic polishing machine manufacturer, and has been well received by users. EP100 series AC servo drive is our company's earliest series of products put into the market, after long-term market test, product performance is stable and reliable, simple to use. The driver PCB board has been treated with three-proof treatment before leaving the factory, which can run stably under relatively harsh working conditions compared to other brands. This case practice proves that Meixin servo drives are used in the polishing machine industry, and there is no abnormality in the normal operation under the working conditions of dusty and high humidity (see Figure 3).