Application introduction

With the increasing degree of industrial automation, robotic arms are more and more commonly used in various industries. The truss manipulator occupies a small area and can be flexibly used for material handling, workpiece flipping, loading and unloading, workpiece transfer processing, etc. It can save labor costs and improve production efficiency. It is especially suitable for the processing of large quantities and small parts, such as automobile gearbox gears, bearing sleeves, brake discs, metal stamping structural parts, etc.

Process requirements

1. It is required to start quickly, high acceleration, and fast linear movement;

2. The corner is stable without jitter, and the large inertia can also start and stop smoothly;

3. High temperature, high dust, heavy oil pollution, no abnormality in all-day work.

Truss manipulator application case 1

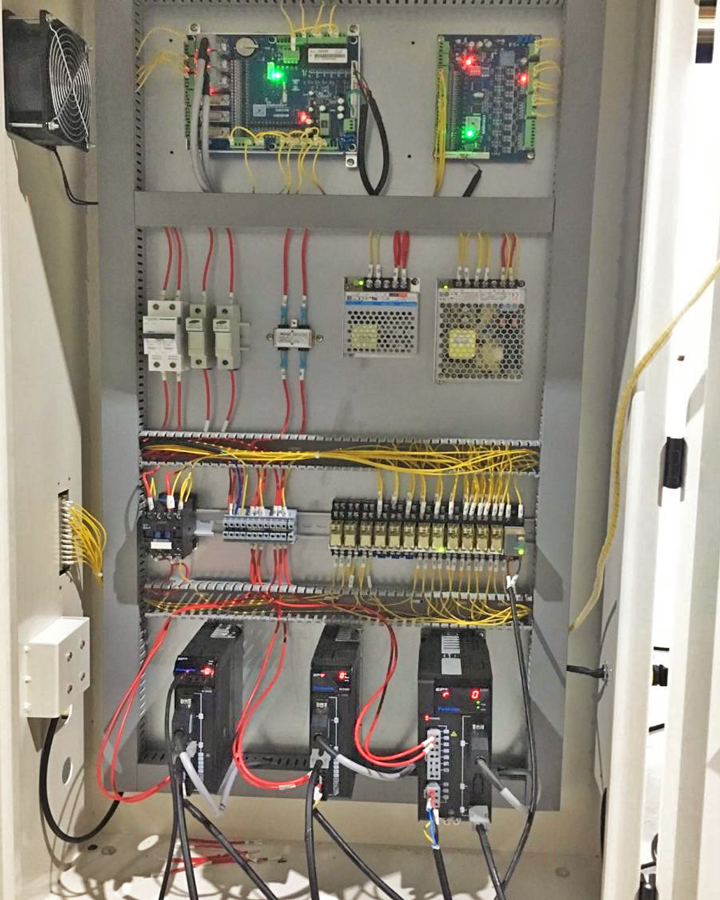

Truss manipulator application case 1 wiring

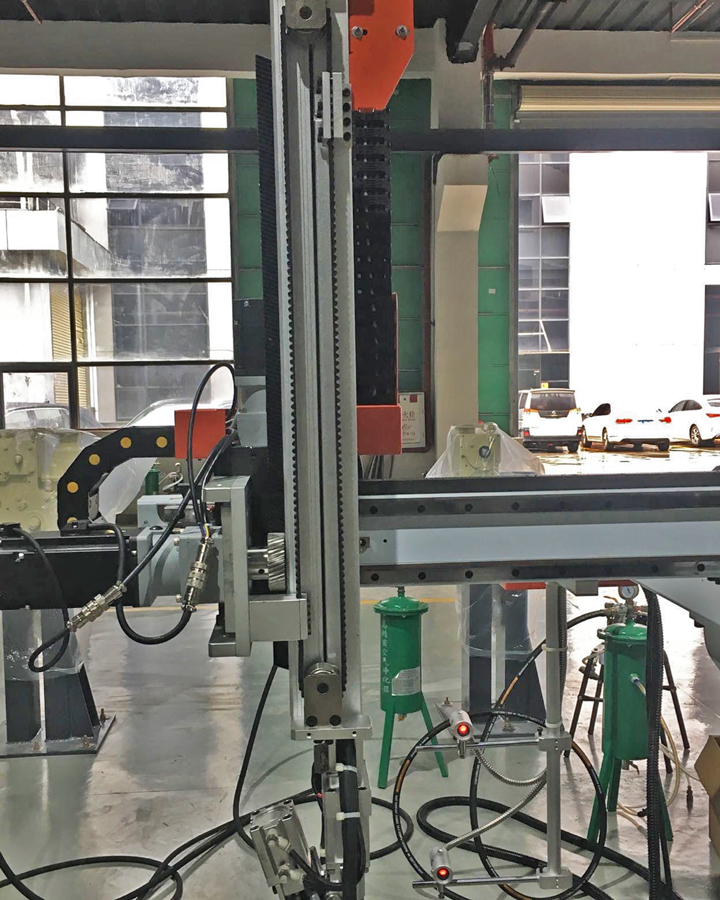

Truss manipulator application case 2

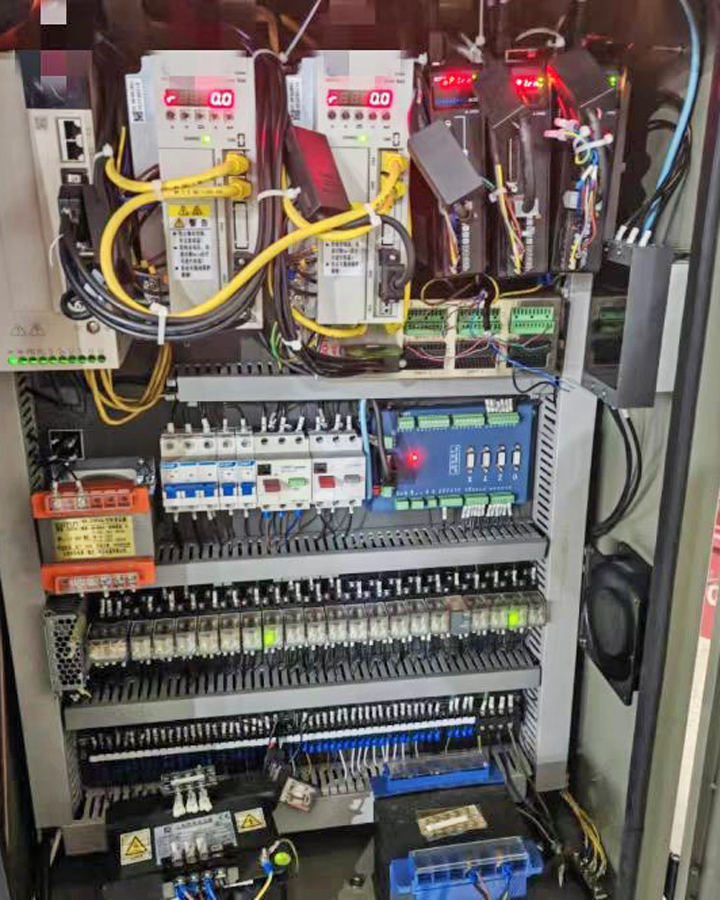

Truss manipulator application case 2 wiring

Truss manipulator application case 3

Truss manipulator application case 3 wiring

Scenario advantages

1. Support pulse, CANopen, EtherCAT and other control modes, can be matched with various types of truss controllers;

2. Support remote firmware upgrade, convenient maintenance;

3. Bus products use spring crimping terminals, and IO interface is free of soldering.