一、Application introduction

An edge sewing machine is a device in textile machinery that uses a sewing machine to stitch the fabric by folding it in half. The feeding and folding parts of the traditional sewing machine rely on manual completion, which not only has low production efficiency, but also has high cost.

Taking MX series PLC and servo system as the platform, a complete set of automatic folding seam machine control system is designed.

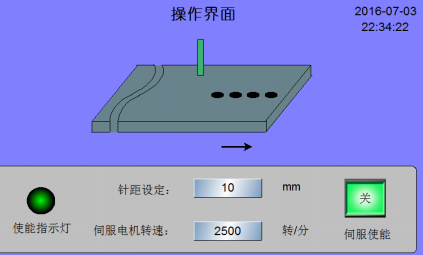

The system automates feeding, hemming, sewing and fabric collection.

二、Process requirements

1. High position accuracy, no crimping, no folding in half, to ensure long-term stable operation

2. The motor reaches 3000r/min per minute and runs at high speed

3. With HMI design, reasonable and simple operation

三、System scenario

四、Device Description MX1N Series PLC

1. Versatility small PLC body points 14/24/40/60

2. Support 2-axis 100K high-speed pulse output

3. Support expansion module to add special functions

4. Support analog control mode

5. Built-in 8000 steps storage space

6. Up to 100 instructions make programming more convenient

7. 100% compatible with Mitsubishi corresponding series PLC