一、Device description:

The machine is widely used in medicine, health care products, food, cosmetics, stationery, audio and video products and other industries of a variety of single large box items packaging or multiple small box items collection film packaging (with gold cable).

二、Device features:

The work of the machine is completed by a series of cams inside the machine to drive various connecting rods and components, using multi-function digital display frequency conversion stepless speed regulation, PLC programming control technology, automatic boxing, automatic counting, touch display to achieve man-machine interface, pneumatic film falling; And can be used in connection with other production lines. Its wide range of packaging, instead of manual packaging, for large enterprises, small and medium-sized enterprises to achieve packaging automation, improve the production efficiency of all walks of life, greatly reduce costs.

三、System composition:

The system is mainly composed of a servo drive and motor and related connecting rod drives.

四、System working principle and wiring:

The system mainly sends position command pulses by the upper computer, and controls the servo motor to drive the transmission device (the position pointed by the arrow in the figure) to control the length of the lower film. Combined with the transmission of the cam below, complete the packaging of tea and other products that need to be plasticized outside.

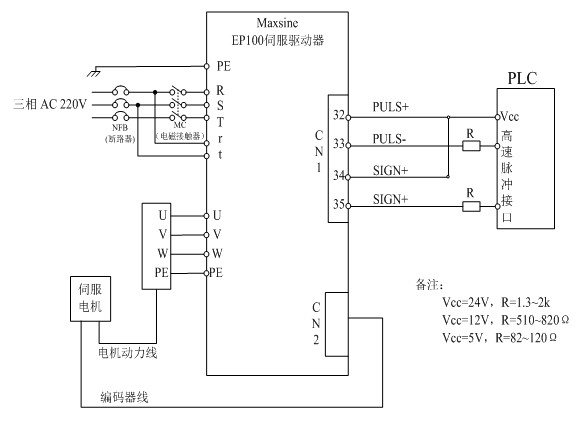

The relevant wiring diagram of the system is as follows:

五、The relevant parameters are as follows: (for EP100)

|

功能代码

|

代码名称

|

设定参数

|

使用说明

|

|

PA01

|

型号代码

|

2A-30

|

同伺服电机相匹配

|

|

PA04

|

控制方式选择

|

0

|

位置控制

|

|

PA05

|

速度比例增益

|

150

|

设置值越大,则刚度越大,过大容易出现振荡

|

|

PA06

|

速度积分时间常数

|

20

|

设置值越小,则刚度越大,过小容易出现超调

|

|

PA09

|

位置比例增益

|

100

|

设置值越大,则刚度越大,过大容易出现振荡或超调(速度控制无效)

|

|

PA12

|

位置指令脉冲分频分子

|

1

|

设置相应值可以很方便的与各种脉冲源相匹配

|

|

PA13

|

位置指令脉冲分频分母

|

1

|

设置相应值可以很方便的与各种脉冲源相匹配

|

|

PA14

|

位置指令脉冲输入方式

|

0

|

设置与上位机相应的脉冲输入方式,默认为脉冲+方向

|

|

PA15

|

位置指令脉冲方向取反

|

0

|

改变此参数可以很简单的改变电机的旋转方向

|

|

PA53

|

低4位输入端子强制ON控制字及正反转驱动禁止

|

1101

|

强制使能及正反转驱动禁止

|